About us

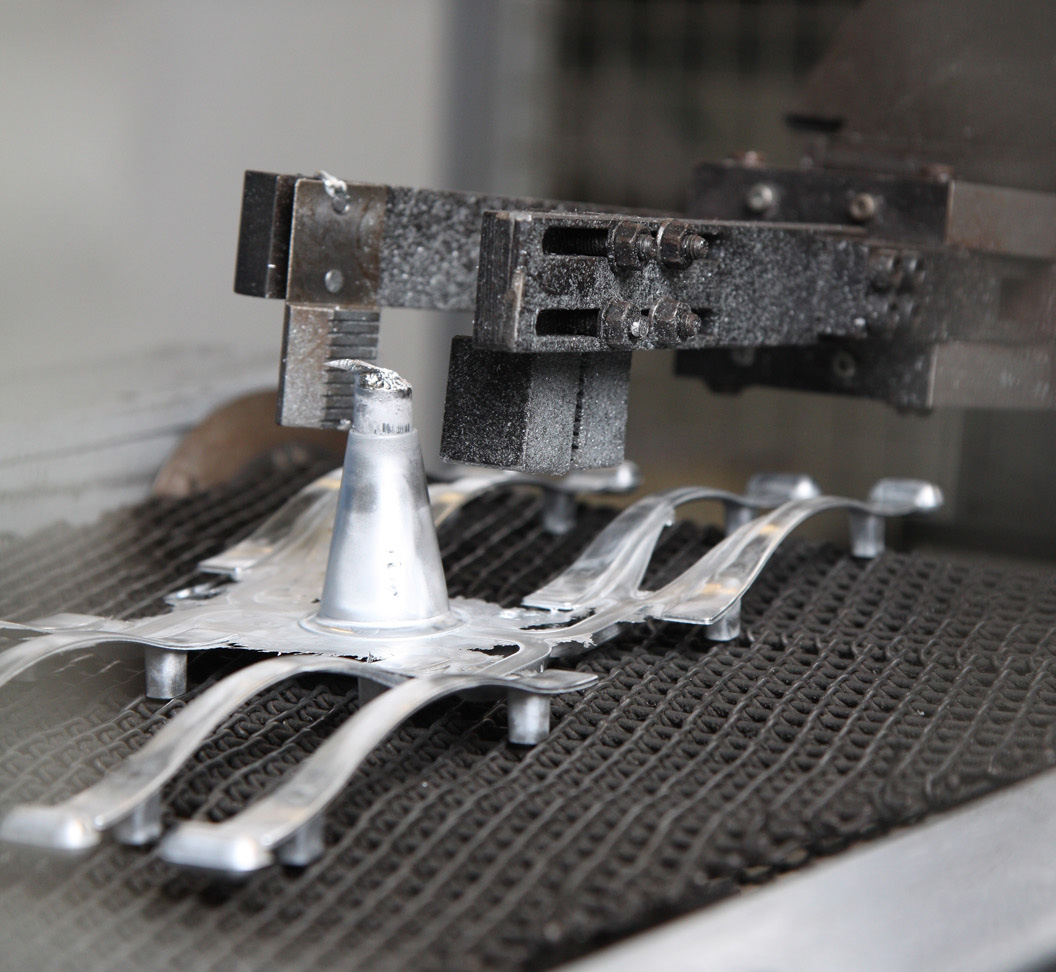

GAMET is a leading European manufacturer of decorative furniture and buildings accessories. For over 30 years of activity, we have gained experience within the scope of casting products made out of zinc and aluminium alloy (ZAMAK), aluminium and plastic materials. We also provide mechanical treatment, as well as galvanized and painted finishes in house.An important part of our activities include the b2b services for the variety of industry sectors. The company has successfully passed several technical and production audits. An important part of our activities include the b2b services for the variety of industry sectors. The company has successfully passed several technical and production audits.

We look forward to working with you!